Couplings are mechanical components that ‘couples’ two drive components which empower a movement to be moved to start with one component then onto the next. The drive components are regularly shafts.

We will, in general, observe part of utilizations of the coupling chiefly in the cars, for instance, the drive shaft which interfaces the motor and the back pivot in a transport or any vehicle is associated by methods for a widespread joint.

So as to transmit torque between two shafts that either will in general lie in a similar line or marginally skewed, a coupling is utilized.

In view of the region of utilizations, there are different sorts of coupling accessible. However, they are commonly classified in the accompanying assortments

1. Rigid Couplings:

2. Flexible Couplings:

3. Rigid Couplings:

Rigid Couplings are fundamentally utilized in zones where the two shafts are coaxial to one another. There are numerous sorts of coupling that fall under the rigid coupling classification. They are

• Rigid Sleeve or Muff Coupling:

This is the fundamental kind of coupling. This comprises of a pipe whose drag is done to the necessary resistance dependent on the pole size. In light of the utilization of the coupling, a keyway is made in the drag so as to transmit the torque by methods for the key.

Two strung gaps are given so as to secure the coupling position. The photograph demonstrates a sort of unbending sleeve or muff coupling.

• Flanged Coupling:

The coupling fundamentally comprises of two flanged end pieces as appeared in the figure. A nozzle and break are given in the spines to give area between them.

The spines are associated solidly by methods for fitted jolts which are fixed as needs be to the torque to be transmitted.

Adaptable or Compensating Coupling:

Adaptable coupling are regularly utilized in zones where the coaxially between the interfacing shafts isn’t constantly guaranteed and in regions where there is a possibility of event of stuns in the transmission is relevant.

They are additionally called as Elastic Coupling. By development, these coupling will, in general, have a versatile part in the middle of the two associating elements. The various kinds of adaptable coupling are

1. Flanged Pin Bush Coupling

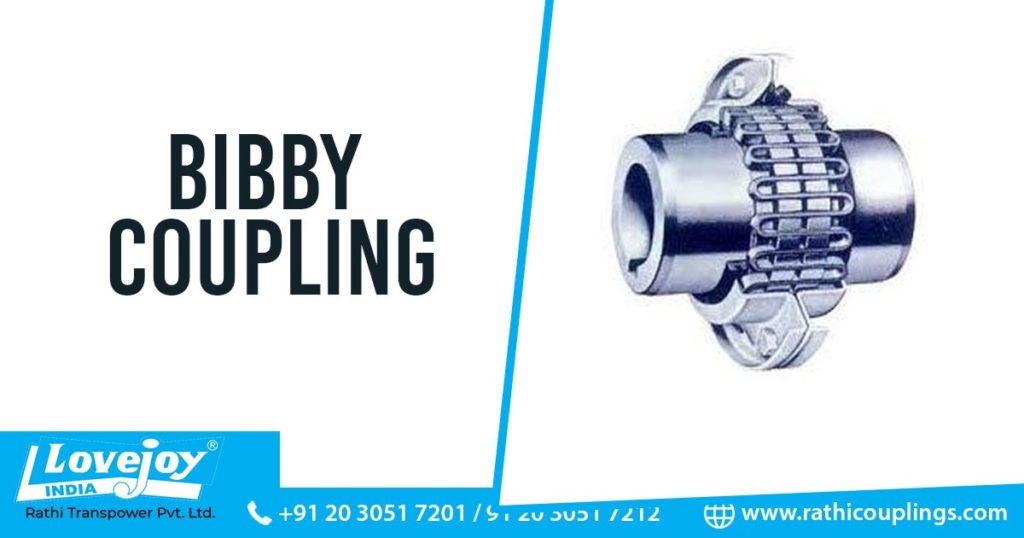

2. Bibby Couplings

3. Rigging Tooth Coupling

4. Tire Coupling

6. Oldhams Coupling

7. General Coupling or Hooke’s Coupling

8. Roars Coupling

Every one of the above coupling is very novel in their development and we can bargain in detail on their constructional and working angles in independent articles.

Lovejoy Rathi Couplings are acclaimed as one of the top coupling manufacturers of India. Lovejoy Rathi Coupling are the pioneer in Coupling Manufacturing in India